Deva Technocast Process Of Investment Casting

-

Wax Injection

- Indigenous Wax preparation technology for better quality wax pattern & stable dimensions.

- Fresh pattern wax for manufacturing of wax patterns for better quality, dimensions & surface finish.

- Centrally Air Conditioning Unit for control of Temperature in entire wax injection, inspection & storage area.

-

Wax Assembly

- Indigenous Wax Assembly system with proper Identification & traceability for separate materials throughout the process.

- Recycled wax is used for assembly of wax patterns to utilize used wax.

-

Ceramic Coating

- Centrally Air Conditioning Unit & Dehumidifier for control of Temperature & Humidity in entire Ceramic Coating & drying area.

- Indigenous Ceramic coating technology for better quality of ceramic shell strength with inadequate permeability & better surface finish of castings.

-

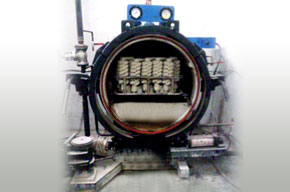

Dewaxing

- Autoclave & Boiler unit for dewaxing for better quality of shells to control cracks during dewaxing of shells.

-

Melting & Pouring

- 250 KW Induction Furnace with three crucibles [300 Kg., 250 Kg. & 150 Kg.]

- 175 KW stand by Induction Furnace for emergency breakdown.

- Oil / Gas fired Shell Baking Furnace.

-

Fettling & Heat Treatment

- In-house LPG Fired Bogie Hearth type Heat Treatment Furnace with 500 Kg. Batch for Solution Annealing, Normalizing & Annealing.

- Separate Electric Heat Treatment Furnace for Tempering at controlled temperature.

- In house separate shot blasting, grinding & pneumatic grinding facility for stainless Steel & Carbon steel.